Summary

In Australia in 2026, many people ask how much does 3D printing cost in Australia, and the answer depends on part size, technology, material, finishing, and quantity. Small FDM parts typically start around $30–$150, while larger or industrial parts using SLS or metal 3D printing can range from hundreds to many thousands of dollars. The main reason for these price differences is that when you buy something you are paying for more, than the material it is made of.

You are also paying for the time the machine takes to make it. The people who make it are skilled. They need to be paid too. Then there is the setup and the work that needs to be done after it is made which is called post-processing.. Finally the company checks the product to make sure it is good, which is quality control. So the price of the product includes all these things: material, machine time, skilled labour, setup, -processing and quality control.

FDM is usually the most affordable option for prototypes and functional test parts. SLA costs more but delivers smooth surfaces and fine detail, while SLS is designed for strong, production-ready nylon parts. Home 3D printing can be cost-effective for frequent, simple jobs, but professional 3D printing services often provide better value for one-off, large, or high-precision parts. Understanding how pricing works helps avoid surprises and supports better decisions.

Key Takeaways

-

FDM is the cheapest 3D printing method for most basic parts

-

SLA is best for detail, but costs more due to resin and finishing

-

SLS is ideal for strong nylon parts, with higher industrial pricing

-

Part size and print time impact cost more than material alone

-

One-off prints cost more per unit than small batch orders

-

Home printing is cheaper only if you print often

-

Professional services offer predictable quality and pricing

-

Clear requirements and detailed quotes save money

-

Forge Labs provides transparent pricing and reliable results across Australia

How Much Does 3D Printing Cost in Australia in 2026?

If you’re expecting 3D printing to cost just “a few dollars of plastic,” Australia in 2026 can be a surprise.

For small FDM parts, local 3D printing services often start around $30 to $150. For industrial work, especially SLS nylon or production-grade parts, prices can quickly reach the thousands.

The reason is simple. You are not just paying for material. You are paying for machine time, setup, skilled labour, finishing, and reliability.

This guide answers the real question: how much does 3D printing cost in Australia in 2026, explained in plain and simple language.

You will find out how much it costs to do 3D printing in Australia. This includes the cost of types of 3D printing like FDM, SLA, SLS and metal 3D printing. You will also learn why the prices of printing services can be so different.

We will look at the prices in cities, like Melbourne, Sydney, Brisbane, Perth and Adelaide. There are some examples that will help you understand why the prices can be so high.

You will also learn how to make 3D printing cheaper. We will talk about printing costs and whether it is better to buy your own 3D printer or use a company that does 3D printing for you. This article is written for beginners, startups, engineers, product designers, and businesses.

Quick Answer: Average 3D Printing Costs in Australia (2026)

In Australia, 3D printing prices usually range from AUD $3 to over AUD $10,000, depending on part size, technology, and job requirements.

Small plastic parts using FDM typically cost between $30 and $150. Functional plastic parts range from $40 to $450. Resin prints with high detail usually fall between $50 and $1,500. Nylon and industrial SLS prints often range from $300 to $10,000 or more. Metal 3D printing usually starts around $300 and can go much higher.

These are realistic market ranges, not fixed prices.

Typical 3D Printing Prices in Australia by Part Size and Method

Most Australian 3D printing shops do not use one simple formula. They combine material cost, print time, operator time, finishing, and shipping.

A useful way to think about cost is part size, not just weight.

Small parts under 10 cm usually cost $30 to $150 with FDM or SLA, while SLS often starts at $300 and can reach $1,500. Medium parts between 10 and 30 cm range from $120 to $450 for FDM or SLA, and $400 to $1,800 for SLS. Large or complex parts often cost $300 to $1,500 or more with FDM or SLA, and $800 to $10,000 or more with SLS.

This explains why two parts that look similar can receive very different quotes.

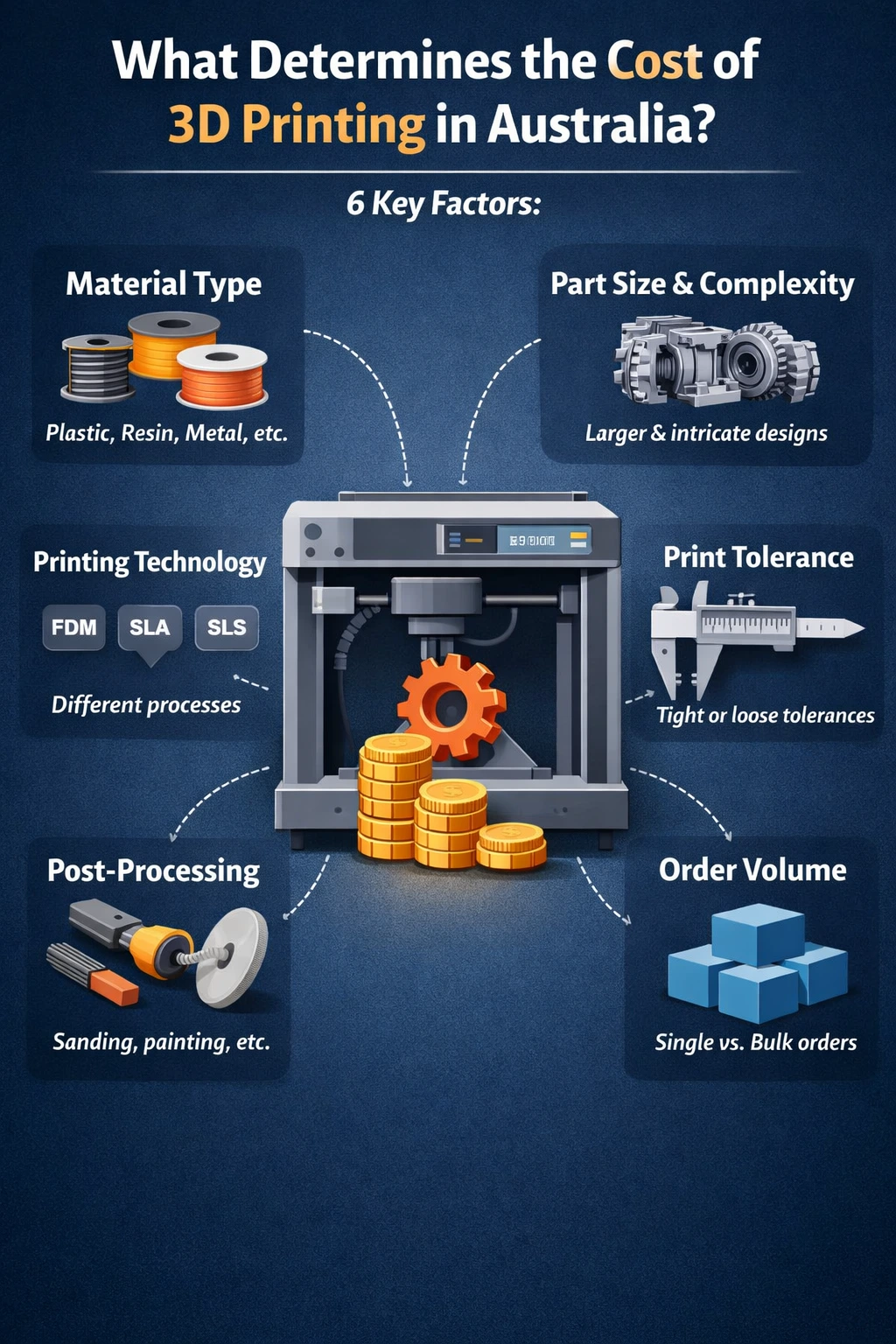

What Determines the Cost of 3D Printing in Australia?

3D printing prices are based on real work and real risk, not guesswork.

Material cost is one of the main factors. PLA and PETG are cheaper materials. Resin costs more. Nylon and carbon-fibre blends cost even more. Metal powders are very expensive. The more material your part uses, the higher the cost.

Machine time also plays a big role. Most services charge between $30 and $150 per hour. High-detail parts take longer to print, and industrial machines cost more to operate. A part that is twice as big is often far more than twice the cost because print time increases rapidly.

Labour and file setup are hidden costs many people overlook. Shops must check files, fix STL errors, plan orientation, generate supports, and monitor the print. Even a small job requires skilled handling.

Post-processing and finishing add cost quickly. This can include support removal, sanding, resin washing and curing, painting, dyeing, or installing threaded inserts. For SLA prints, finishing can cost as much as the print itself.

Failed prints and material waste are also included in pricing. Not every print works the first time, and good providers price this risk so you receive a usable part.

3D Printing Cost by Technology in Australia

FDM 3D printing is usually the cheapest option. One-off FDM prints typically cost between $30 and $150. Common materials include PLA, PETG, ABS, and carbon fibre blends. FDM is best for prototypes, jigs, fixtures, and test-fit parts. While raw filament is cheap, billable material includes supports, purge material, and handling.

SLA or resin 3D printing costs more because of cleanup and curing work. Prices usually range from $50 to $1,500. SLA is best for miniatures, cosmetic prototypes, dental-style models, and parts that need smooth surfaces and fine detail. Large resin parts become expensive quickly due to long print times and fragile handling.

SLS nylon 3D printing is usually the expensive way to do things. You can expect to pay $800 to get started and it can cost more than $10,000 for big parts or parts that are made for production. SLS nylon 3D printing is really good for making nylon parts that have complicated shapes and do not have any marks from supports. The reason SLS nylon 3D printing costs much is because of the machines handling the powder and making sure everything is consistent, with SLS nylon 3D printing.

Metal 3D printing is always quote-based. Prices usually start around $300 and increase based on material, size, and certification needs. Metal printing is used for aerospace, medical, and engineering applications.

Why One-Off Prints Cost More Than Small Batches

This is a major pain point for buyers. A single bracket might cost $180, while ordering 40 units could drop the price to $80 each.

This happens because setup time, machine preparation, and admin work are spread across more parts. Batch printing allows better printer bed packing and reduces repeated checks. As quantity increases, the cost per part usually decreases.

The Real Cost Drivers That Increase Quotes Fast

High quotes are rarely caused by expensive plastic. They usually come from large size, thick walls, high infill, heavy supports, difficult orientation, tight tolerances, or cosmetic finishing.

A smart question to ask is whether relaxing surface finish or splitting the part into multiple pieces would reduce cost. Good print shops will explain the trade-offs clearly.

File Readiness, Supports, and Finishing Costs

Clean files print cheaper. Non-manifold geometry, thin walls, unclear tolerances, and poor design increase labour time.

Supports add cost through extra material and extra cleanup. If you only need a test-fit or functional prototype, say so. Skipping cosmetic finishing can save significant money.

Rush Jobs, Shipping, and Compliance in Australia

Fast turnaround usually costs more because shops must rearrange their schedule. Resin parts need careful packing to avoid damage during shipping. Compliance requirements such as material certificates, repeatability documentation, or engineering sign-off add admin and inspection costs. For simple prototypes, these steps are often unnecessary.

Real Cost of Owning a Home FDM 3D Printer in Australia (2026)

When people search for 3D printing cost Australia 2026 or how much does 3D printing cost in Australia, many are also comparing professional services with buying their own printer.

Home FDM 3D printing has become more affordable in Australia, but the real cost is not just the printer price. It includes setup, filament, electricity, maintenance, and time.

In many cases, home printing looks cheap at first, but professional 3D printing services Australia price can be lower overall for one-off parts, large prints, or high-quality requirements.

3D Printer Price in Australia (2026)

If you are checking 3D printer price Australia 2026, these are realistic ranges for FDM machines.

Entry-level FDM printers usually cost $300 to $600 AUD. These are suitable for learning and small parts.

Mid-range FDM printers typically cost $700 to $1,400 AUD, offering better reliability and auto bed levelling.

Upper mid-range or prosumer printers often cost $1,500 to $3,000 AUD, with faster speeds and stronger build quality.

You do not need the most expensive machine to get good results. Stable motion, a heated bed, and reliable electronics matter more than premium branding.

Is Home 3D Printing Really Cheaper in Australia?

Home printing can be cheaper if you print often, but it is not always the cheapest option.

Filament usually costs $30 to $60 per kg for PLA or PETG. Electricity use is low, often less than $1 per long print. Maintenance costs such as nozzles and cleaning supplies add a small but ongoing expense.

If you print occasionally, professional cheap 3D printing Australia services often make more sense because you avoid failed prints, setup time, and wasted material.

3D Printing Cost Per Hour in Australia (Home vs Service)

At home, the cost per hour is mainly filament and electricity, usually a few dollars per hour at most.

Professional services calculate 3D printing cost per hour Australia very differently. Most service providers charge between $30 and $150 per hour, depending on the printer type, resolution, and supervision required. This hourly rate includes machine depreciation, labour, and quality control.

This explains why professional quotes look higher but deliver predictable results.

FDM vs SLA Cost in Australia (Home and Professional)

Understanding FDM vs SLA cost Australia helps avoid overpaying.

FDM is the cheapest option for most parts and is ideal for prototypes, brackets, and test-fit parts.

SLA costs more due to resin material and post-processing but delivers smoother surfaces and fine detail.

For cosmetic prototypes or dental-style models, 3D printing resin cost Australia is higher but often justified by finish quality.

Metal and Industrial Printing Cost in Australia

For searches like metal 3D printing cost Australia, it is important to know that metal printing is always quote-based.

Metal 3D printing typically starts around $300 AUD and increases rapidly based on size, material, and certification. It is used mainly for aerospace, medical, and engineering applications where strength and precision matter.

Prototype and Small-Batch Printing Costs

Many startups search for 3D printing prototype cost Australia.

Single prototypes usually cost more per unit because setup and checking time is not shared. Small batch orders reduce per-part cost significantly. This applies to both home printing and professional services.

City-Based Pricing Considerations

Location also affects 3D printing price Australia.

For 3D printing Melbourne cost, prices are often competitive due to many service providers.

For 3D printing Sydney price, costs may be slightly higher because of labour and operating expenses.

For 3D printing Brisbane cost, pricing is often moderate with growing service availability.

City differences are usually smaller than differences caused by part size, material, and finishing.

Home Printing vs Professional 3D Printing Services in Australia

Home FDM printing works well for frequent, simple prints where small imperfections are acceptable.

Professional 3D printing services Australia price are usually better for:

-

One-off parts

-

Large components

-

Resin or SLS nylon parts

-

Tight tolerances

-

Customer-ready finishes

Many users combine both approaches. They print early prototypes at home and use professional services like Forge Labs for final parts, stronger materials, or reliable batch production.

Snapshot Comparison: Cost Table for Major 3D Printing Technologies

|

Technology |

Typical Part Cost (Small–Medium Size) |

Material Cost Level |

Setup / Prep Cost |

Post-Processing Cost |

Best For |

Key Limitations |

|

FDM |

Low |

Low |

Minimal |

Low–Medium (support removal, sanding) |

Basic prototypes, brackets, jigs, large low-detail items |

Visible layer lines, lower accuracy |

|

SLA |

Low–Medium |

Medium |

Moderate |

Medium–High (washing, curing, sanding) |

High-detail prototypes, smooth surfaces, visual models |

Brittle materials, support marks |

|

SLS |

Medium |

Medium–High |

Moderate |

Low–Medium (bead blasting, media finishing) |

Strong nylon parts, functional prototypes, complex shapes |

Surface finish is grainy unless finished further |

|

MJF |

Medium |

Medium–High |

Moderate |

Medium (dyeing, smoothing options) |

Batch runs, functional nylon parts, fixtures |

Colour options limited without add-ons |

|

PolyJet |

Medium–High |

High |

High |

High (support gel removal, cleaning) |

Visual models, colour parts, rubber-like materials |

Costly materials and slower builds |

|

DMLS / SLM (Metal) |

High |

Very High |

High |

High (support removal, machining, heat treatment) |

Metal components, tooling, aerospace/industrial use |

Most expensive category, long finishing steps |

|

CNC (Reference) |

Medium–High |

Material-dependent |

High |

Medium–High |

Precision parts, tight tolerance needs |

Less efficient for complex organic shapes |

Why Forge Labs Is the Best Choice for 3D Printing in Australia

Most problems people have with 3D printing are not about material.best 3D printing services in Australia They come from unclear pricing, poor communication, delays, and parts that do not match expectations.

Forge Labs stands out because of clear quoting, help choosing the right printing method, basic design checks before printing, consistent quality, and honest explanations of what you are paying for.

Instead of vague numbers, Forge Labs breaks down material cost, print time, and finishing work. If you want reliable 3D printing services in Australia, Sydney, Melbourne and Brisbane with predictable results, Forge Labs is one of the best places to start.

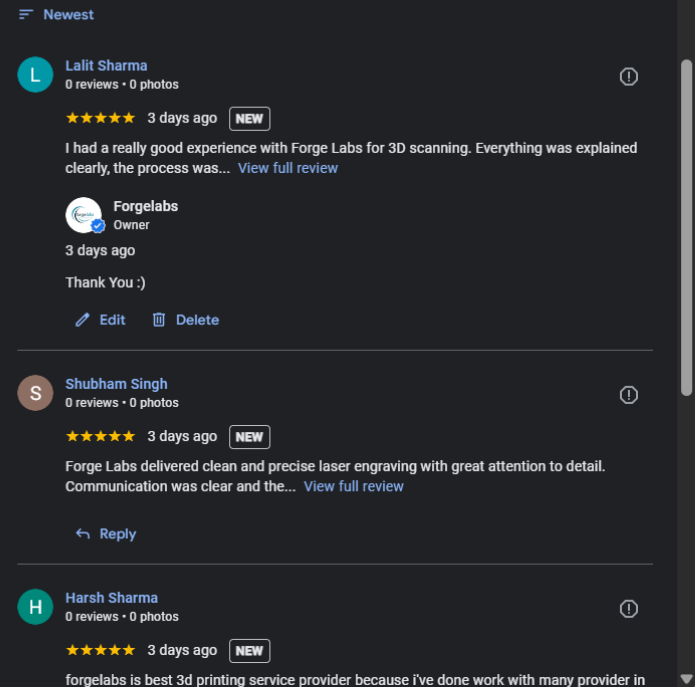

What Customers Say About Forge Labs

“We were looking for the best 3D printing services provider in Melbourne for functional prototypes. Forge Labs explained the costs clearly, suggested small design changes to save money, and delivered exactly what we needed on time.”

— Product Designer, Melbourne

“Forge Labs is easily one of the most reliable 3D printing services in Sydney. The quote was transparent, the turnaround was fast, and the parts matched our drawings perfectly. No surprises, no delays.”

— Engineering Consultant, Sydney

“After comparing multiple 3D printing companies in Australia, we chose Forge Labs for a small batch run. The quality, communication, and pricing clarity made them the best 3D printing service provider we’ve worked with so far.”

— Startup Founder, Brisbane

Contact Us

-

+61416945444

-

contact@forgelabs.com.au

About the Author

This article is written by the Forge Labs team, with 15+ years of combined experience in professional 3D printing services across Australia. The team works with engineers, designers, startups, and manufacturers in Melbourne, Sydney, Brisbane, and beyond, delivering reliable FDM, SLA, SLS, and industrial 3D printing solutions with transparent pricing and consistent quality.

(Last reviewed in 2026 to reflect current 3D printing prices, materials, and service practices in Australia.)

FAQs: 3D Printing Cost in Australia

What is the cheapest way to 3D print in Australia?

FDM printing in PLA with a simple design and no finishing is usually the cheapest option.

How do 3D printing shops price jobs?

Most shops use a mix of per-gram material cost, per-hour machine time, setup charges, and finishing costs.

Why is SLS 3D printing expensive?

SLS machines and materials are costly, and the process includes powder handling and long machine cycles. You pay for strong, consistent nylon parts.

How much does 3D printing cost in Australia in 2026?

3D printing cost in Australia in 2026 ranges from about $30 for small FDM parts to $10,000+ for large industrial SLS or metal parts, depending on size and technology.

What is the cheapest 3D printing option in Australia?

FDM printing in PLA with simple geometry is usually the cheapest form of cheap 3D printing Australia.

What is the average 3D printing cost per hour in Australia?

Professional services typically charge $30 to $150 per hour, depending on the machine and material.

How much does resin 3D printing cost in Australia?

3D printing resin cost Australia usually ranges from $50 to $1,500, depending on part size and finish.

Is home 3D printing cheaper than using a service?

Home printing can be cheaper if you print often. For occasional jobs or high-quality parts, professional services are usually more cost-effective.

Does 3D printing cost vary by city in Australia?

Yes. 3D printing Melbourne cost, 3D printing Sydney price, and 3D printing Brisbane cost vary slightly due to labour and demand, but part size and material matter more.

Final Thoughts: What to Budget for 3D Printing in Australia in 2026

In Australia in 2026, 3D printing costs are no longer a mystery when you understand what drives them. FDM remains the most affordable option for prototypes and functional test parts. SLA is the right choice when surface finish and fine detail matter, and SLS is built for strong, production-ready nylon parts where reliability is critical. There is no single “cheap” or “expensive” method, the right process depends on what the part must do.

Your final 3D printing price is shaped by part size, print time, material choice, supports, finishing requirements, and quantity. Most unexpected costs come from unclear requirements, rushed timelines, or choosing a printing method that does not match the real use case of the part.

This guide was written to remove that confusion. Every section is based on real-world quoting experience, common customer questions, and practical decisions faced by businesses, engineers, and startups in Australia. Instead of theoretical pricing, the focus is on how 3D printing services actually calculate cost, why quotes vary, and how small decisions can significantly change the final price.

When you are making something you need to think about what the part's going to do not just what it looks like.

You should pick the way it is printed based on what it needs to do, not how it needs to look. Get the amount of parts so you can get a good deal when they are all made at the same time. Also ask for a quote that tells you about the material, how long it takes to print and what else needs to be done to it.

Following these steps can save you a lot of time and money with your printing part. For those who want dependable quality, transparent pricing, and professional guidance, Forge Labs is a trusted choice for Best 3D printing services in Australia. The goal is not just to print parts, but to help you make informed, cost-effective decisions, whether you are producing a single prototype or scaling toward production.